Our history

goes back to the year 1990

Even back then, as a medium-sized, family-run industrial computer manufacturer, we recognized that industrial companies require particularly robust and reliable hardware due to increasing automation. After all, the same demands are placed on industrial PCs as on machines and production systems.

Over 30 years ago

this is how the success story in Bavaria began

P3 – 1990

P4 – 1995

P5 – 1998

N6- 2001

N7 – 2004

N8 – 2006

N10 – 2011

N11 – 2015

The design and manufacture of completely enclosed industrial PCs without external fans, which meet the special requirements of an industrial environment, was the consequence of these needs. In order to successfully continue this development, the current noax Technologies AG was founded in Ebersberg near Munich in 1998.

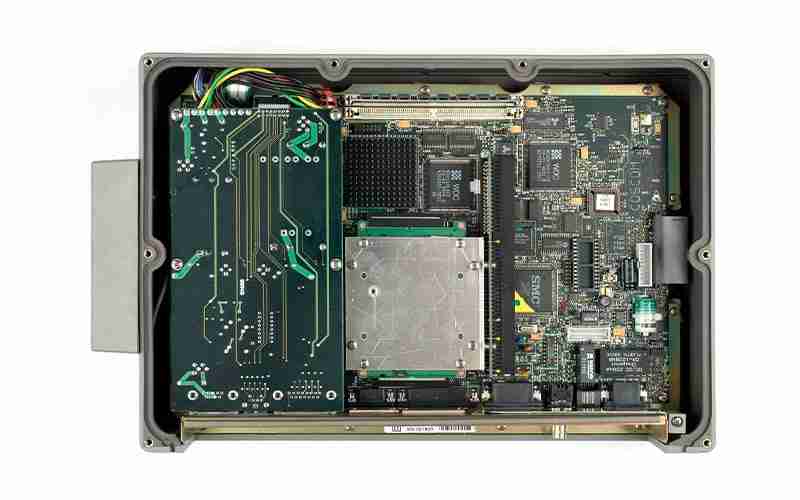

From the very beginning, our goal has been to manufacture extremely compact industrial computers with high computing power that are easy and intuitive to use. To achieve this goal, we influence every detail: from the initial design to the finished product. In this way, we can always produce innovative products, bring them to market, and continuously set new standards. For example, our first manufactured industrial PCs of the 1990s already featured integrated touch operation as well as intelligent thermal management that met the high demands of industrial companies worldwide.

We are happy to pass on these decades of experience in the development, manufacture and sale of industrial PCs for extreme operating conditions to our customers in the form of high-quality products.

We always want to offer you industrial computers that are state of the art and that are absolutely durable. We therefore place the highest demands on the quality of our IPCs. We pay great attention to ensuring that the entire process chain is in our hands: from development, through production and sales to after-sales service.

That is why we now have a variety of innovative, robust and reliable products and enjoy an excellent reputation with our customers worldwide. We gain numerous new customers through recommendations from existing and satisfied customers. Industrial PC User reports from a wide range of industries provide impressive evidence of this.

Through continuity in our company and proximity to our customers, we have not only been able to assert ourselves in a demanding market, but have even grown steadily. In addition to our headquarters in Ebersberg near Munich, we are personally available to our customers in our European and American branches.

In-house development

made in Germany – from the very beginning

A key cornerstone of our success is the in-house development and manufacture of our industrial PCs. With the philosophy “From the idea to the finished product” – made in Germany. This includes the mechanical and electronic components right through to the motherboard. Due to this great depth of development and the fact that we manufacture in Germany, we have the necessary influence on all components in order to meet our quality standards.

Mechanics – Electronics – Quality management

The three pillars of noax IPC in-house development

In-house development and a strict quality management system in-house in Ebersberg near Munich are for us as an IPC manufacturer the guarantors of the robustness of our hardware. We pay particular attention to:

Mechanics

-

Many years of experience in the development of industrial PCs with high protection classes – IP66, IP67 and IP69K

-

Sustainable construction with a focus on shock and vibration resistance

-

Long-term and trusting cooperation with our suppliers to ensure the highest quality of the individual components.

Electronics

-

Development of own all-in-one motherboards

-

Careful selection of electronic components and circuit parts according to our high requirements

-

Ensuring electromagnetic compatibility (EMC), long-term availability of at least 5 years

Quality management

Industrial PCs pass extreme tests

As an industrial PC manufacturer, we subject our industrial PCs to extreme tests, which are precisely documented and then analyzed. During the tests, for example, predefined temperature curves are run in combination with different degrees of humidity over a longer period of time. Various shock and vibration tests are also carried out in order to simulate later practical use in advance. Our high quality standards are reflected in the certificates issued by independent institutes, approvals such as CE, FCC, IP66, IP67, IP69K, and last but not least in our numerous, satisfied customers.